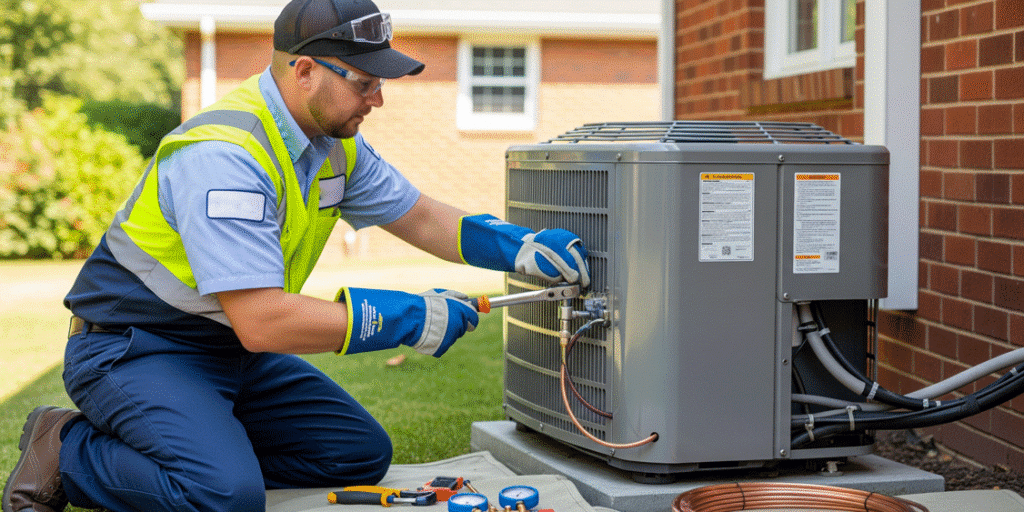

Installing an air conditioner may appear to be a simple process, yet without the appropriate AC installation tools, even professionals may make expensive mistakes and system failures. The poor performance, refrigerant leaks, and warranty problems are the problems that many homeowners and contractors cannot cope with, due to the absence of appropriate equipment.

This complete manual has shown the 5 critical AC installation equipment that will ensure the best quality of professional results, which will allow you to have the best cooling that will serve you over the years without having to use costly repairs and call-ins.

Getting Started with AC Installation Tools

Air conditioner installation is a professional job, and the equipment needed is well beyond simple hand tools. These accuracy tools guarantee your cooling system to be efficient, safe, and reliable for many years to come.

What Are AC Installation Tools and Why Do We Need Them

The special tools used in HVAC systems are known as AC installation equipment. These are not common tools; they process the refrigerants, they create the correct seals, they can find the leakages, and they offer the maximum working of the system. Without them, installations would be expected to break down after a matter of few months as they would be contaminated, leaked, or interconnected wrongly.

Why Using the Best Tools Makes AC Work Smoother

Quality “air conditioner installation tools” save common issues such as loss of refrigerant, contaminated moisture, and electrical problems. These are used to maintain the correct vacuum levels, correct pressure readings, and no leaks. The professional tools also shorten the period of installation and minimise the likelihood of making expensive errors that would invalidate the manufacturer’s warranties.

How to Choose Quality AC Installation Tools

In deciding on the right equipment to utilize in your projects with regards to your AC unit installation you need to take into consideration durability, accuracy and long term value. Quality tools represent a single fee payment that provides reliable performance and reduced rates of callbacks.

Look for Durable and Trusted Brands

Select manufactures with a good reputation of HVAC equipment. Locate apparatus of metal, fine gauges, complete warranty. Such brands as Yellow Jacket, Robinair, and Fieldpiece are durable tools, which can be utilized every day and which could be correct in years of use.

Balance Price with Long-Term Value

Although the premium AC installation tools are expensive to acquire initially, they are much more precise and durable. Divide costs by usage in a few years instead of the cost of purchase. Quality tools minimize the number of calls, system failures, and its overall performance in resale value, as compared to less expensive options.

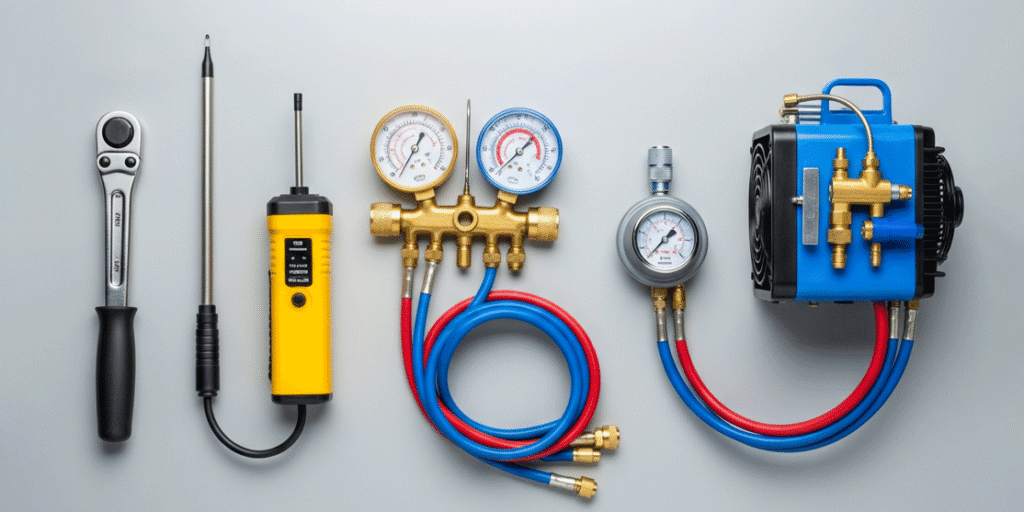

5 Best AC Installation Tools for Professional Quality Results

1. Micron Gauge (The Tiny Air Finder)

The micron gauge is used to measure the drop levels of deep vacuum that are critical in the correct process of AC installation. This is an accurate gauge that identifies moisture and air contamination that cannot be identified using a normal gauge. It will guarantee that its system is vacuumed down to the 500-micron level necessary to achieve maximum efficiency.

Key features to include:

- Digital reading with 1-micron precision.

- Shut off by default in case of oil backflow.

- Precision qualification of calibration.

- Field use construction Durability.

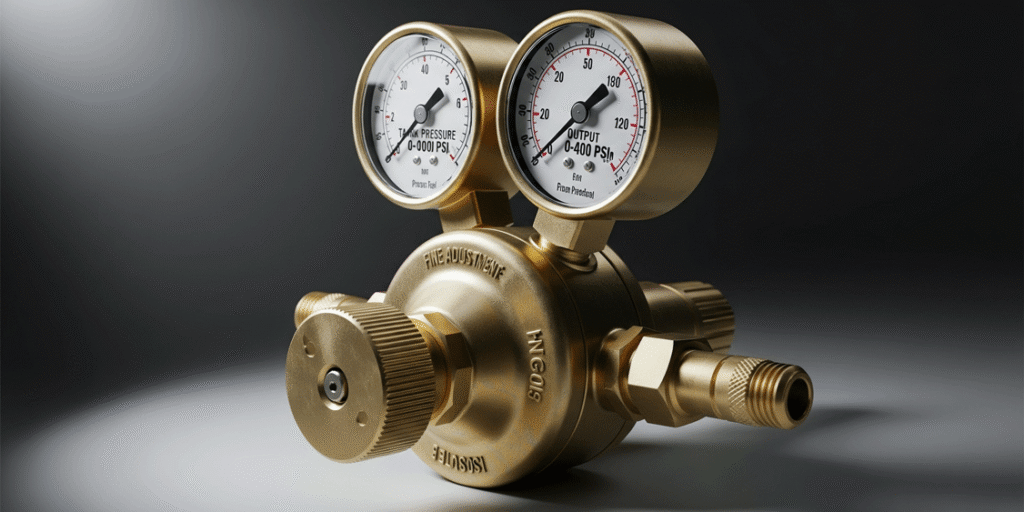

2. Nitrogen Regulator (The Special Gas Controller)

This is a special regulator that regulates the flow of nitrogen during pressure tests and purging activities. It helps to avoid oxidation in the course of brazing and provides clean and contamination-free installations. Professional air conditioner installation demands exact pressure regulation, and only special nitrogen regulators offer it.

Essential specifications:

- Pressure range 0-800 PSI

- Control valve Fine adjustment.

- The construction is made of brass to be durable.

- Several outlet connections.

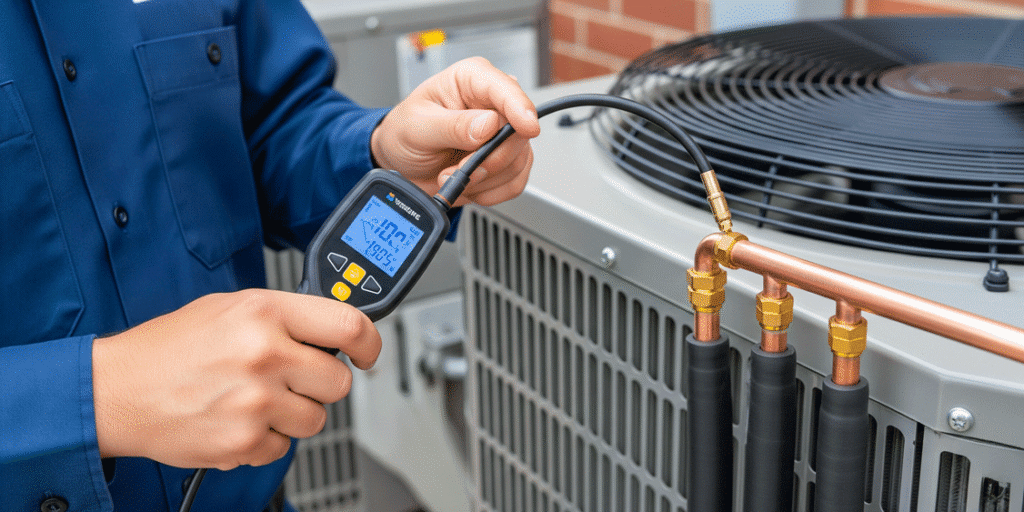

3. Electronic Leak Detector (The Gas Escape Finder)

The electronic leak detectors identify the refrigerant leaks that cannot be detected by the soap solutions. These delicate devices read concentrations as low as 0.1 oz/year, avoiding system malfunctions and pollution of the environment. All AC unit installations must be leak-tested using professional leak detectors.

Important features:

- Multi-refrigerant compatibility

- Auditory and visual loss indicators.

- Bendable probe to fit the narrow places.

- Portability Battery powered.

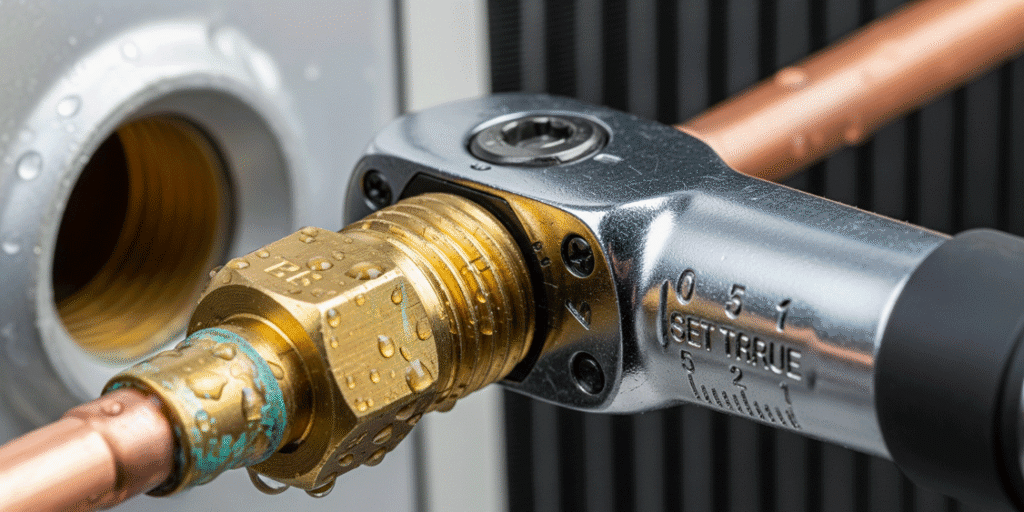

4. Torque Wrench (The Perfect Tightness Tool)

Torque wrenches are used to ensure that connections are made properly without being over-tightened, resulting in broken seals. They are essential to flare nuts, service valves, and electrical connections. Correct torque values ensure no leakage is caused, but do not result in stripped threads that would cost a lot to fix.

Required specifications:

- 15-150 ft-lb torque range

- ±3% accuracy rating

- Rapid-disassembling ratcheting head.

- Comfortable grip design

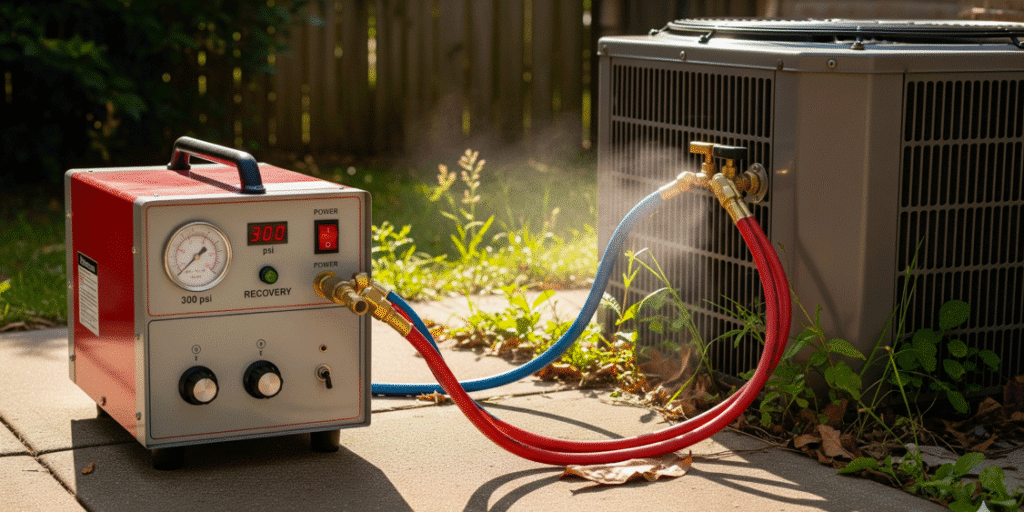

5. Refrigerant Recovery Machine (The Gas Saver Box)

EPA regulations entail the recovery of refrigerant during the service and installation. These are safe machines used to safely remove and store refrigerant at the expense of the environment. Refrigerant is also purified using professional recovery machines, which enable reuse and save a significant amount of operating expenses.

Essential capabilities:

- Satisfactory recovery rate (2 + lbs/minute)

- In-built purification system.

- Multiple compatibility with refrigerant.

- Oil separator and filter

AC Unit Installation Made Simple

Appropriate AC installation tips can reduce complicated projects to simpler activities. The systematic approaches and use of quality tools will guarantee successful installation at all times.

Easy Steps to Install an AC Unit the Right Way

Professional air conditioner installation works on pre-tested steps that reduce mistakes and guarantee maximum efficiency. This is applicable in residential and commercial applications in combination with redundant tools.

Installation sequence:

- Mounting of both indoor and outdoor units.

- Connect refrigerant lines that are well insulated.

- Install electrical connection according to the code.

- Nitrogen pressurized test system.

- Blow dry system to good vacuums.

- Refrigerant according to the manufacturer’s specifications.

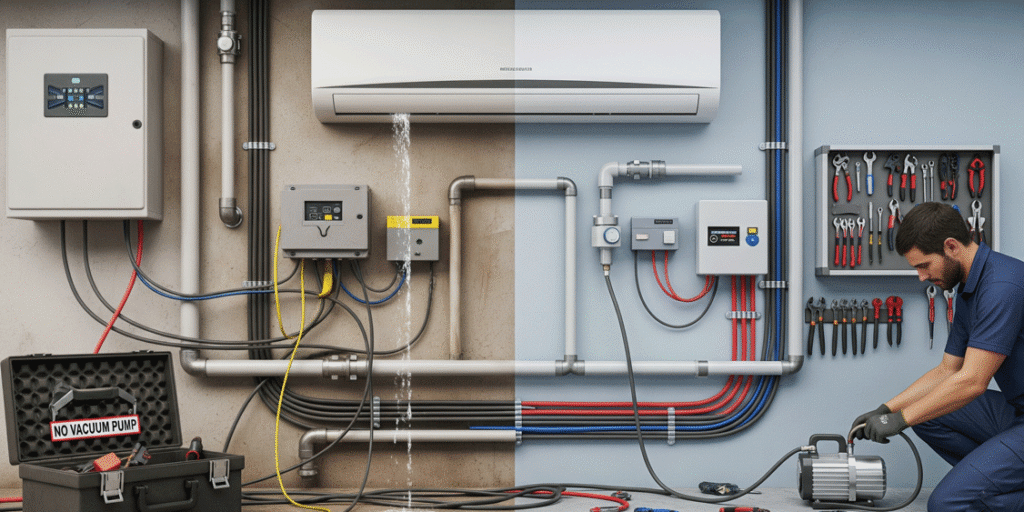

Common Mistakes to Avoid During AC Installation

Even highly trained technicians commit such mistakes that affect the performance of the systems. The knowledge of these pitfalls will make the process of successful completion of an AC installation process successful and prevent costly recalls.

Mistakes that should be avoided the most:

- Omission of due vacuum procedures.

- Lack of proper charging of refrigerant.

- Poor connection of electricity.

- Weak installation of drainage systems.

- Disregard of the manufacturer’s specifications.

- Hurrying leakage detection processes.

Extra Air Conditioner Installation Tools You Might Need

Handy Tools for Special AC Installation Jobs

Some installations need more AC installation equipment than the five simple tools. Hard-to-reach places, special system setups, or manufacturer specifications may require some special tools to complete successfully.

Safety Gear That Keeps Everyone Protected

The professional air conditioner installation equipment consists of the necessary safety gear that helps to safeguard the technicians and equipment. Do not put safety equipment to the test when dealing with electrical systems, refrigerants, and high installations.

Essential safety equipment:

- Side shielded safety glasses.

- Insulated electrical gloves for voltage.

- Electrical protective non-slip safety footwear.

- Enclosed space respirator mask.

- Eye wash solution, First aid kit.

Understanding the AC Installation Process from Start to Finish

Simple Steps from Planning to Final Testing

The AC installation process is a complex task that requires proper planning, sequential implementation, and complete testing. The professional outcomes must be paid attention to, detailing every step, starting with the first measurements up to the final performance checks.

When to Call a Professional for Better Results

Complex systems are known to need specialized technicians and equipment. Our company (AC Maintenance UAE) offers professional skills when dealing with difficult projects where accuracy and integrity are the main factors. They have highly trained technicians who apply professional AC installation tools in order to make sure that the installations comply with all the specifications of the manufacturer and the local codes.

Frequently Asked Questions

Q1. Which tools are the most essential AC installation tools for a beginner?

Micron gauge, basic manifold set, torque wrench, electronic leak detector, and recovery machine: The professional look.

Q2. Do you have any standard tools that you can use in the projects of installing an air conditioner?

No, air conditioner installation is a specialized job that involves the use of specialized tools that do not cause any harm to the refrigerants and make the system work properly.

Q3. What is the required frequency of the calibration or servicing of AC installation tools?

Calibrate precision instruments and service recovery machines according to the manufacturer’s instructions in order to keep them accurate.

Q4. What is the most serious mistake a person makes when selecting the AC installation equipment?

Purchase of cheap tools that wear out easily or do not have the accuracy required to install the AC units professionally.

Conclusion

Key Points to Remember Before Starting Your Project

Successful cooling system installations require quality “AC installation tools. The five tools mentioned, such as the micron gauge, nitrogen regulator, electronic leak detector, torque wrench, and recovery machine, are the basis of professional-grade work that guarantees long-term reliability and performance of the system.

Final Thoughts

The quality of professional outcomes is determined by the application of proper ac installation equipment along with the systematizing process and safety measures. Although the cost of the initial tools might be a bit on the higher side, these are compensated for with little time taken to make the calls, taking a shorter time to install them, and delighted customers who are having a wonderful experience with the cooling system that is reliable.

This is how to choose and use professional AC installation tools, and now it is time to feel confident about your next cooling project. Begin to develop your professional set of tools today and feel the difference in quality equipment in all installations.

AC Maintenance UAE Team

Welcome to AC Maintenance UAE, your reliable partner for complete air conditioning repair and maintenance services in Dubai, Sharjah, and Abu Dhabi. We are strongly dedicated to excellence and deliver efficient and reliable services to keep your cooling systems performing at their best.

- AC Maintenance UAE Team

- AC Maintenance UAE Team

- AC Maintenance UAE Team

- AC Maintenance UAE Team